Vacuum & Controlled Atmosphere Solutions

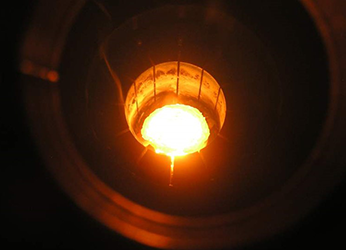

Melting & Processing High Performance Metals & Alloys

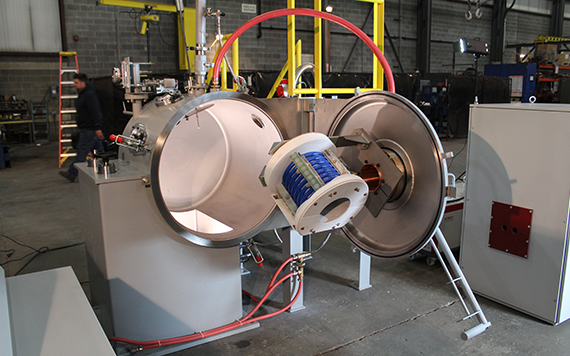

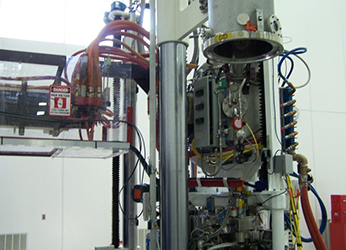

Ajax TOCCO Magnethermic has been a recognized leader in the design, manufacture, service, and rebuild of induction furnace systems and specialized ancillary equipment for the metals industry’s most demanding applications. Through innovation in engineering, materials science, and customer-driven service, we maximize the reliability of induction melting and heating equipment, systems, and solutions.

Utilizing extensive knowledge of controlled atmosphere thermal processing, our experienced engineers work alongside customers to define and meet demanding application requirements, providing comprehensive solutions from initial research and development through in-house assembly and total system testing.

Advanced Metals & Materials

Induction Vacuum and Controlled Atmosphere Processes provide an ideal solution for the thermal processing of many advanced materials and specialty metals. We specialize in engineering, manufacturing, and integrating specialty equipment for a variety of unique atmosphere conditions. The following are some examples of advanced metals and materials that benefit from a vacuum or controlled atmosphere:

- Master/Superalloys: Heat resistant alloys based on nickel (Ni), iron-nickel (Fe-Ni), or cobalt (Co) that exhibit a combination of mechanical strength and resistance to surface degradation at elevated temperatures. These are primarily used in gas turbines, coal conversion plants, and chemical process industries, as well as other specialized applications requiring high heat and corrosion resistance.

- Reactive Metals: Materials that readily combine with oxygen at elevated temperatures to form stable oxides, such as with titanium, zirconium, and beryllium. Reactive metals may also become embrittled by the interstitial absorption of oxygen, hydrogen, and nitrogen. Reactive metals and their alloys are often processed using induction cold wall crucible (skull melting), plasma hearth or electron beam melting, and refining methods.

- Rare Earth Metals: Include the group IIIA elements scandium, yttrium, and lanthanide elements in the periodic table. The primary application for rare earth metals is as an alloying additive. Materials that rare earths are added to include ductile iron (modify carbon morphology), superalloys (increase operating temperatures), magnesium alloys (improve creep resistance), aluminum alloys (improve tensile strength and corrosion resistance), oxygen-free and high-conductivity copper (improve oxidation resistance), and dispersion-strengthened materials (improve high temperature properties).

- Intermetallic Metals: Possess a narrow range of homogeneity and relatively simple stoichiometric proportions; the nature of the atomic binding can be of various types ranging from metallic to ionic. Intermetallic compounds constitute a unique class of metallic materials that form long-range ordered crystal structures below a critical temperature.

- Hydrogen Storage Alloys: Metallurgically designed to absorb and release hydrogen (in hydride form) without compromising their own structure. Since some alloys have the capability of storing hydrogen at an even higher density than pure hydrogen, hydrogen storage alloys represent an excellent solution for fuel cell storage. The most common forms that hydrogen storage alloys take are in NdFeB (neodymium iron boron), lithium ion, or NiMH (nickel metal hydride) batteries used in everyday consumer electronic products. The most effective means for manufacturing such alloys is through a controlled atmosphere powdered metallurgy processes.

- Semiconductor Materials: Encompass a wide range of ceramics, metals, metalloids, and complex compounds whose electrical resistivity is intermediate between that of a conductor and an insulator. Semiconductor materials involve combinations of nearly all the elements in groups IIB, IIIA, IVA, VA, and VIA of the periodic table. The variety of elemental combinations results in a wide range of properties (electrical, optical, thermal, and mechanical). Common commercial semiconductor materials include; Germanium, Silicon, Gallium Arsenide, Selenium, Silicon Carbide, Cadmium Sulfide, Indium Antimonide, Lead Sulfide, Bismuth Telluride, Lead Telluride, and Mercury CadmiumTelluride.

- Precious Metals: Also known as noble metals, consist of the following; ruthenium, rhodium, palladium, silver, osmium, iridium, platinum, and gold.

- Radioactive Materials: Such processes involve the consolidation and/or vitrification of contaminated materials.

- Graphites: Graphite is a crystalline allotropic form of carbon. The production of graphite requires high temperature processing within an inert atmosphere environment.

- Aluminides: Titanium aluminides and other intermetallic metals.

- Nitrides: Boron nitride, silicon nitride, carbon nitride, aluminum nitride, titanium nitride, and zirconium nitride.

- Carbides: Compounds of carbon with one or more metallic elements.

- Ceramics: A class of inorganic non-metallic products, which are subjected to high temperature during manufacture or use. Typically, but not exclusively, a ceramic is a metallic oxide, boride, carbide or nitride, or a mixture of compound of materials that includes anions that play important roles in the atomic structure and properties.

Vacuum & Controlled Atmosphere Systems

Visit our product pages for information on our Vacuum and Controlled Atmosphere Systems. We provide systems for the most demanding metals industry applications. Ajax TOCCO engineering specialists can determine the best fit for your demanding application requirements.

%20(1)-1.png)