Induction Water Systems

Why A Water System Is Crucial For Induction Equipment

Quantity of Water Required – Cost & Local Restrictions. Frequently, the savings realized by using a recirculating/cooling water system allow the system to pay for itself in a year or less if city water is the alternative. In some geographical areas, both the amount of water taken from the main and the amount discharged to the drain are regulated, making a water system worth the investment.

Quality of Water - Water quality varies greatly in different parts of the world. It’s important to analyze the source of the water that will be used to charge the system to determine if it meets the requirements of an induction system.

The following water properties are important factors in maintaining efficient induction systems.

- Temperature – if the water is too cold, condensation results and electrical components can be short-circuited. If the water is too warm, damage can result from equipment overheating. Our induction equipment typically requires the water temp to be between 75°F and 105°F.

- Hardness – Experience with thousands of installations has shown that when water hardness exceeds 100 PPM CaCo3, water flow and cooling are impeded due to mineral build-up in the water passages.

- Suspended Particles – Likewise, greater than 10 PPM will also impede cooling efficiency due to build-up problems.

- PH Level / Acidity – "Acidic" water (pH level less than 7) can cause corrosion in piping. "Basic" water (pH level greater than 7.5) can cause deposits on inner piping walls. Therefore, pH should be maintained between 7.0 and 7.5 for optimum water system operation.

- Oxygen & Compounds - Oxygen dissolved in the water is a leading cause of corrosion and can also contribute to biological growth. Some compounds, such as ammonia, can be very detrimental, even in small amounts.

- Resistance or Conductivity - To prevent ground readings and electrochemical corrosion, which can be an expensive maintenance problem, resistance on most systems should be tightly controlled.

- Pressure – The water pressure can affect cooling efficiency. Too little, and insufficient cooling can result, which can damage expensive components. Too much can cause leaks and hoses to blow. Ideally, the water pressure should be between 30 to 70 PSIG and remain constant. Brief drops in pressure will cause the equipment to de-energize.

Which Water System To Choose?

Many times, selecting the right water system can be as important as selecting the right melting or heating equipment. Water is crucial for the efficient operation of most heating and melting systems. There are open-loop, closed-loop, and modified closed-loop designs consisting of different configurations of pump stations and heat exchanger types. Experienced application engineers help determine the correct configurations based on the system parameters.

Open, Closed, Or Modified Closed-Loop

When dealing with induction systems, open-loop systems are typically only used as a secondary system if there is already a heat exchanger in place. Because the water is open to the air in the reservoir tank, oxygen is delivered to the ferrous components in the system, often causing deterioration and corrosion. With an open loop, the water is subject to evaporation from the reservoir, requiring additional water to be added. If the new water isn’t distilled or deionized, it can result in high conductivity or a buildup of solids in the system.

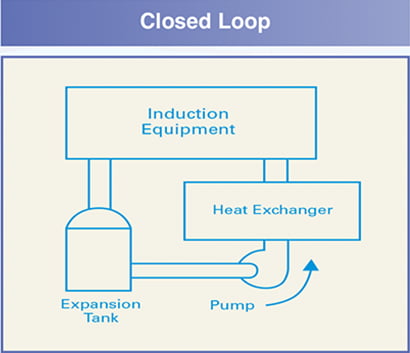

In a closed-loop system, water does not come into contact with air. As a result, water does not deteriorate or evaporate, thus maintaining high quality. Initially, the system is filled with a high-quality deionized or distilled water source, equating to low conductivity and contaminant-free water, which is essential for cooling solid-state power supplies.

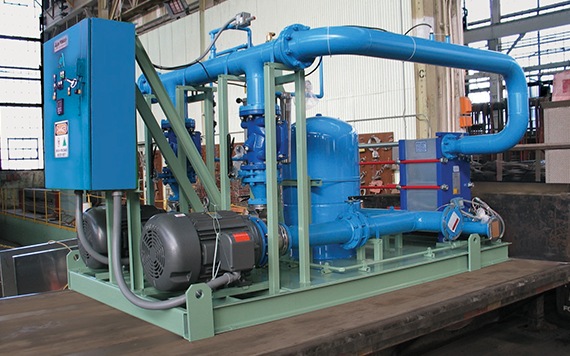

Induction Water System Products

Water system products include different pump recirculating systems and coolers. Multiple configurations of water systems may be utilized. Ajax TOCCO engineering specialists can determine the best fit for your equipment.

.png)

.png)