Brazing & Joining Solutions

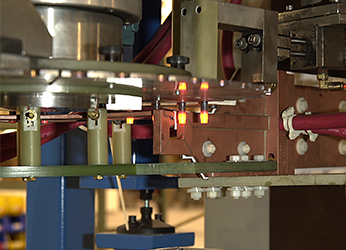

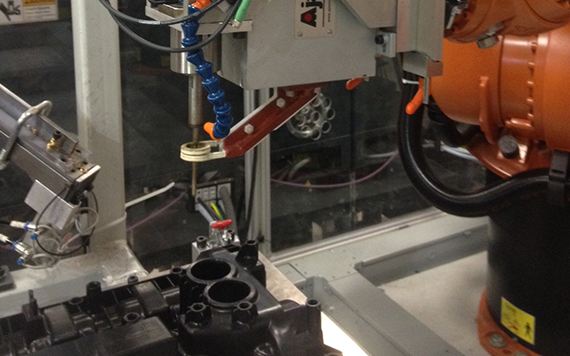

Brazing with Induction

Induction heating offers repeatability when brazing, soldering, and joining. Direct localized heating of the braze area minimizes radiant heat to the environment or work cell. Both high-volume and mixed production processes are compatible with induction for controlled repeatability, strength, and quality. As in any manufacturing system, the proper selection of equipment, combined with good manufacturing practices can lead to safe, long-term, trouble-free, operation.

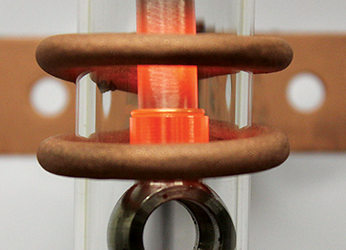

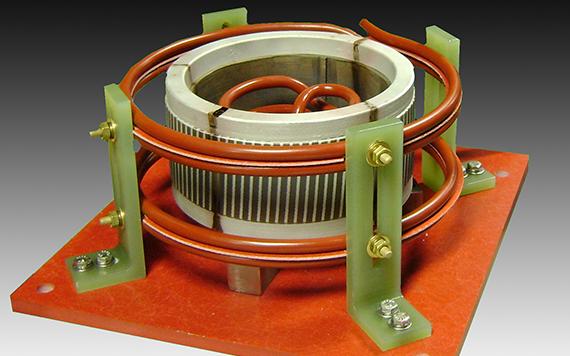

Bonding & Curing with Induction

Induction is used for bonding in many applications. Heating an electrically conductive material can cause an adhesive reaction in a nearby material, causing it to flow or reflow. Increased productivity and smooth, efficient operations are key to our bonding and soldering systems. Induction provides uniform heating resulting in enhanced bond/cure characteristics. Plastic to metal and glass to metal, including the joining of non-conducting materials, is accomplished through direct induction heating or by using a susceptor. Other advantages include accelerated line speeds, reduced line length, and increased quality.

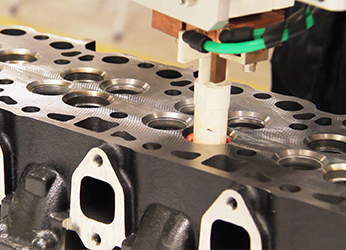

Shrink Fitting with Induction

Shrink fitting is often used to replace conventional mechanical fasteners and fastening methods. Localized heating of the mating surface provides temporary expansion and allows slip-fit assembly. The resulting interference fit exhibits exceptional strength without surface deformation at ambient temperatures.

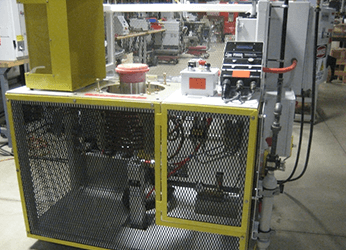

Induction Brazing And Joining Industries

Induction brazing and joining techniques have been used to optimize operations across the globe. From mom and pop shops to automotive manufacturers, no job is too big or too small.