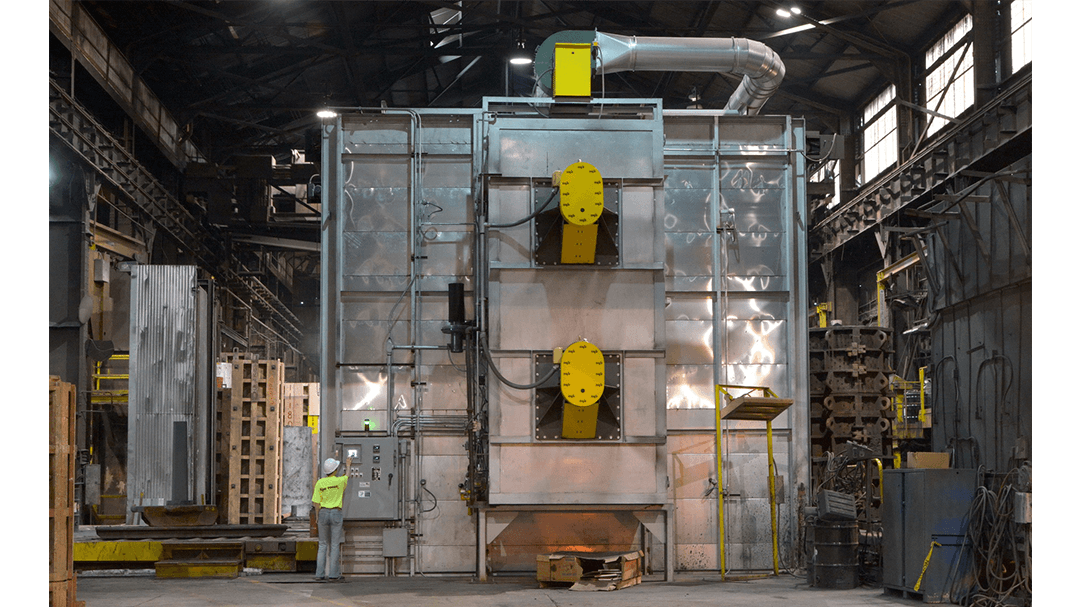

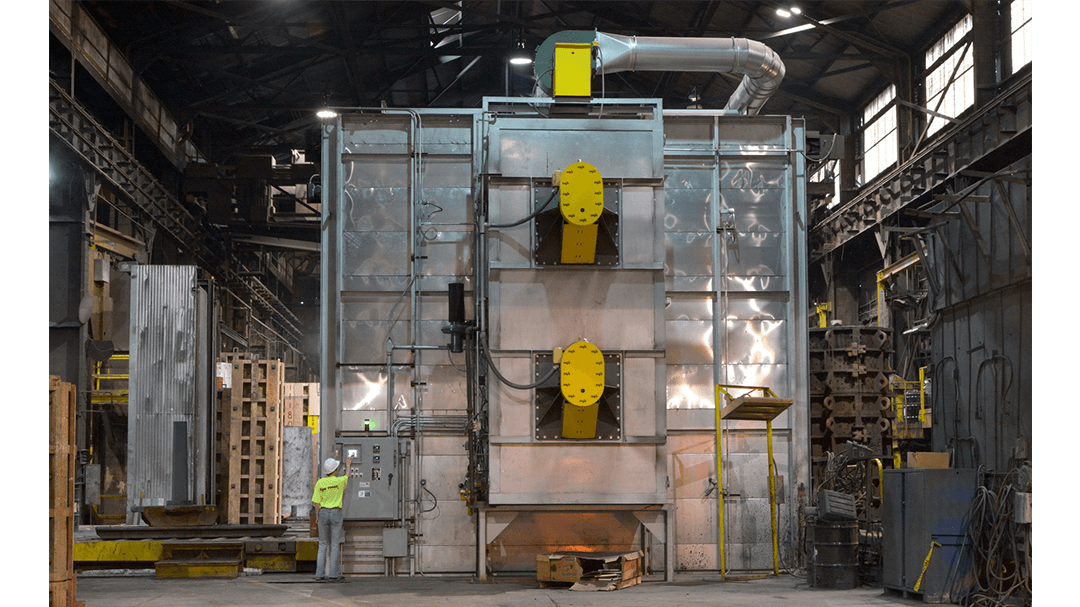

Coating Ovens

Different Types of Coating Ovens

Some basic types of coating ovens, each with its own unique features are:

- Wicket ovens

- Pin up, belt ovens

- Dip spin

- Tiered conveyors

Each oven design uniquely dries and cures a specific coating on a part. Handling and heat application must be balanced to prevent overheating of the part or the coating.

WICKET OVENS are used to carry sheet material in a vertical orientation with only one side touching the “wicket” carrier. The other side is the coated side and is presented to heated air supply at an angle that is suited for the uniform drying of the coating. Because of the vertical orientation of the part, the wicket oven can hold a large number of parts in the heated chamber in a short footprint.

PIN UP, BELT OVENS have very pointed “pins” strategically placed on a metal conveyor belt to support a coated product at very small points. This allows for a part to be coated on both sides while passing through the oven heat chamber. Process air can be applied to both sides at once, reducing the drying time.

DIP SPIN systems are used where small parts are completely coated in a “dip” process, then in bulk are spun to expel excess coating material. The coated parts are dumped onto a conveyor belt that carries them through the oven-drying process. Typically, this process includes a cooler as the parts go directly to packaging after drying.

TIERED CONVEYORS are used for irregularly shaped parts that have deep ridges and pockets where coating can accumulate. A series of “tiered” conveyors tumble these parts as they go through the oven heat chambers, exposing every facet of the part to process air for complete drying. Another advantage to this design is it is well suited for varying temperatures from one conveyor to the other to process those coatings that require a dry and cure “cycle” of temperature.

Resources

Maximize Your Production Efficiency

Thank you for requesting access to this brochure.

You can access your download by clicking here.